VCSEL / Laser

Complete characterization of VCSEL arrays

Laser diodes and VCSELs as technology drivers

Laser diodes are becoming indispensable in a multitude of everyday and industrial applications, thereby expediting new applications and technologies. These include:

- - Facial and gesture recognition in consumer electronics

- - LiDAR (light detection and ranging) in the car

- - Material processing with high-performance diode lasers

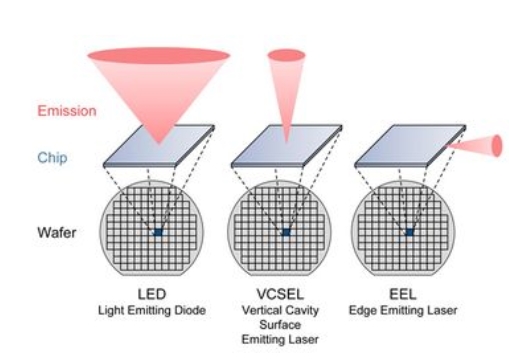

VCSELs are replacing EELs

Laser diodes can be technologically subdivided into EELs (edge-emitting laser) and VCSEL (vertical cavity surface-emitting laser). EELs are edge emitters and emit horizontally to the chip surface. They can be optically characterized only after reflecting surfaces have been attached to the chip edges.

In contrast VCSELs – analogous to LEDs – are surface emitters and emit vertically to the chip surface. The layer structure incorporates the mirror required for the laser cavity. This permits optical characterization of the VCSEL already on the wafer. The VCSEL production process is thus more economical than that of EEL, with the result that they are replacing conventional laser systems in an increasing number of applications. The need for suitable measuring systems for efficient, high-precision optical characterization of these narrow-band light sources is increasing accordingly. As the temporal behavior of laser pulses for many applications is critical, the characterization of the pulse length down to a nanosecond is important.

How should VCSEL arrays be measured?

VCSEL single emitter measurement (near field):

The analysis of single emitters is indispensable for the comprehensive characterization of VCSEL arrays. In order to meet the quality standards of VCSEL manufacturers and integrators in the lab and production they must be measured to determine defects, position, absolute performance and angular range, as well as their single emitter wavelength. Specialized IR cameras are required for the purpose.

VCSEL array measurement (far field):

To guarantee eye safety, the spatial radiation properties of the entire VCSEL arrays must be reliably measured. In the lab this should be done, e.g. with a high-precision goniometer, combined with a high-end spectrometer with traceable calibration. One-shot measurement solutions with a conoscope or transmission screen may be applied in place of the goniometer in production.

Measurement of VCSEL pulses:

Because the temporal behavior of laser pulses is critical for many applications, the characterization of pulse length down to a nanosecond is imperative for VCSEL manufacturers. Suitable measurement systems require excellent spectral resolution, high-performance control electronics and fast photodiodes for power measurement, both in the lab and in production.

Measurement of spectrum and power of VCSEL arrays:

The spectral power of the VCSEL array is measured at special test setups consisting of high-end spectroradiometers and various different integrating sphere configurations. Auxiliary light sources as an extension for self-absorption correction are recommended for greater accuracy.

The challenge: Spectral measurement of laser diodes with a defined error budget and traceability

Measuring systems for laser diodes must satisfy special requirements:

► High spectral resolution

► High throughput volumes in production

► Spectral power measurement of pulsed laser diodes

► 2D analysis of all VCSEL arrays in the near field

► Far-field characterization of VCSEL arrays

Requirements for pulse measurements:

► Very short pulse lengths (≥ 1 ns) at extremely high currents (up to 15A)

► High sampling rates of several gigahertz

► Fast processing of large data volumes for measuring pulse trains